Advanced Welding Inspection Service for Engineering Applications

Advanced Welding Inspection Service for Engineering Applications

Blog Article

Enhance Your Jobs With Specialized Welding Providers: Kinds and Benefits

In the globe of building and construction and production, the relevance of specialized welding services can not be overstated. From complex jobs that require precision to massive industrial applications, the right welding method can make a significant difference in the end result of a project. As improvements in modern technology proceed to form the welding sector, recognizing the kinds of specialized welding solutions available and the advantages they supply is crucial for remaining in advance in an open market. Whether it's the effect on construction tasks, the applications in the production market, or the advantages for numerous fields, discovering the world of specialized welding solutions reveals a world of opportunities that can raise projects to brand-new elevations.

Kinds of Specialized Welding Provider

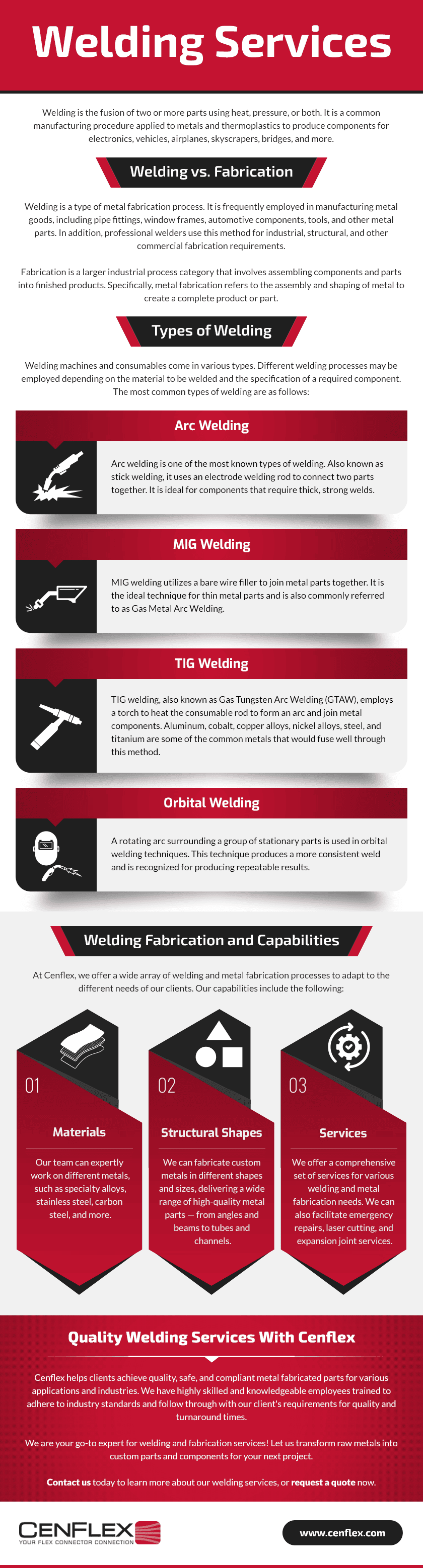

Specialized welding solutions encompass a variety of methods customized to specific industrial applications, consisting of however not restricted to TIG welding, MIG welding, and immersed arc welding. Tungsten Inert Gas (TIG) welding, recognized for its accuracy and clean welds, is typically made use of in sectors needing premium welds on materials like stainless steel and light weight aluminum.

Each of these specialized welding techniques provides distinct advantages tailored to particular job demands, highlighting the value of picking the appropriate technique based on material, thickness, and preferred weld features.

Advantages of Specialized Welding Services

The benefits of utilizing specialized welding solutions in industrial applications are manifold, varying from enhanced precision to enhanced performance in managing specific products and project demands. One significant benefit of specialized welding services is the proficiency and experience that welders offer the table. These professionals are trained in numerous specialized welding techniques, making certain that the welding process is lugged out with the highest degree of ability and precision.

Effect on Construction Tasks

Attracting on the competence of specialized welding solutions in industrial applications, the impact on construction tasks is considerable in terms of accuracy, performance, and overall top quality of welds. Building and construction projects depend greatly on the structural honesty of welded parts, making the accuracy offered by specialized welding crucial. By using specialized welding services, construction groups can guarantee that each weld meets the required specifications, decreasing the danger of structural failings.

Additionally, specialized welding strategies improve performance in building tasks by improving the welding procedure. With specialized equipment and skilled professionals, jobs that would otherwise be lengthy can be finished quicker without compromising high quality. This performance not only increases project timelines however likewise decreases labor expenses connected with welding.

Furthermore, the total top quality of welds in construction jobs is substantially improved with specialized welding solutions. These solutions frequently include sophisticated welding modern technologies and very competent welders that can develop more powerful, more durable welds. The premium high quality of welds accomplished through specialized solutions contributes to the durability and integrity of construction tasks, guaranteeing that structures continue to be risk-free and sound for many years to come.

Applications in Production Sector

Within the manufacturing market, the application of specialized welding solutions plays a vital function in making certain the honesty and efficiency of manufacturing procedures. Welding is a fundamental procedure in production, made use of in different applications such as joining steel parts, fabricating frameworks, and fixing devices. Specialized welding techniques like TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and robot welding are thoroughly employed to meet the sector's details demands.

One considerable application of specialized welding in manufacturing remains in the auto industry. Welding is pivotal in the assembly of vehicle parts, making sure structural security and safety. Additionally, the aerospace sector heavily counts on specialized welding services to fabricate airplane elements with high precision and toughness to hold up against extreme conditions.

Moreover, in the production of machinery and devices, specialized welding plays important link a vital function in developing trusted and resilient items. By using advanced welding approaches, producers can boost product high quality, improve manufacturing performance, and inevitably provide remarkable products to the market - Welding Inspection Service. The specific and complex nature of specialized welding services makes them indispensable in the manufacturing sector's quest for technology and excellence

Advantages for Different Industries

With the pivotal duty that specialized welding services play in the production sector, it is evident that their benefits prolong across numerous fields, supplying vital advantages for different sectors. Specialized welding solutions offer improved precision and quality control, making certain that the last item satisfies rigorous market standards. Furthermore, specialized welding services can assist sectors meet particular governing requirements, such as those in the oil and gas sector or the nuclear sector, where safety and dependability are paramount.

Final Thought

To conclude, specialized welding solutions supply a variety of benefits for building tasks and the production sector. With different sorts of welding solutions offered, such as robotic welding and laser welding, services can boost the top quality and efficiency of their jobs. The influence of specialized welding solutions expands throughout numerous sectors, giving benefits in regards to cost-effectiveness, toughness, and accuracy. Accepting specialized welding services can result in improved project outcomes and enhanced competitiveness out there.

As innovations in modern technology continue to shape the welding industry, recognizing the kinds of specialized welding solutions available and the benefits they provide is vital for staying in advance in an affordable market.Specialized welding solutions include a range of strategies customized to particular commercial applications, including yet not restricted to TIG welding, MIG welding, and submerged arc welding.In addition, specialized welding services often make use of sophisticated tools directory and innovations that are especially created for intricate welding projects. Specialized welding strategies like TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and robot welding are extensively utilized to fulfill the market's details demands.

Report this page